AERO GAUGEPORT UNITS

The pneumatic measurement or air gauging interface units are mostly used for measuring fixtures such as bores, shaft diameter, cylindrical work piece, ovality, and roundness. It is a non-contact measuring technique that performs dimensional and checks of the geometric part.Aero gauge interfaces have two types: with pneumatic and without pneumatic. Aero gauge interface with pneumatic series covers a one, two, four and nine channels unit. The aero gauge interface without pneumatic series covers a four and eight channels unit.Virtually maintenance free, these devices have been in use over many years in industry delivering excellent measurement performance in varying industrial environments.

AERO 111R

AERO 211R

.png)

AERO 411R

AERO 411R

AERO 400R

AERO 800R

AERO 911R

AERO 411R

Products Models

| SR NO. | Product model No. | Description |

|---|---|---|

| Aero gauge port(Built-in air regulator and converter) | ||

| 1 | AERO 111R | Single channel air gauge port,RS232 output. |

| 2 | AERO 111A | Single channel air gauge port,Analog output. |

| 3 | AERO 211R | Two channel air gauge port,RS232 output. |

| 4 | AERO 211E | Two channel air gauge port,Ethernet output. |

| 5 | AERO 211A | Two channel air gauge port,Analog output. |

| 6 | AERO 411R | Four channel air gauge port,RS232 output. |

| 7 | AERO 411E | Four channel air gauge port,Ethernet output. |

| 8 | AERO 911R | Nine channel air gauge port,RS232 output. |

| 9 | AERO 911E | Nine channel air gauge port,Ethernet output. |

| Aero gauge port(Without Pneumatic) | ||

| 1 | AERO 400R | Four channel air gauge port,RS232 output. |

| 2 | AERO 400E | Four channel air gauge port,Ethernet output. |

| 3 | AERO 400A | Four channel air gauge port,Analog output. |

| 4 | AERO 800R | Eight channel air gauge port,RS232 output. |

| 5 | AERO 800E | Eight channel air gauge port,Ethernet output. |

Feature:

- Built-in air electronic, pressure regulator and sensor. (With pneumatic Aero convertor).

- RS-232 serial interface for communication.

- Default baud rate for a system 19200, we can set to maximum 115200 Baud rate using utility.

- Multiple such units can be cascaded in a chained fashion.

- Communication protocols: ASCII continuous transmission.

- Configuration: Through serial interface (RS232) using software utility.

- Ethernet interface (Factory option).

- It’s possible to set scaled resolution using software utility.

- 4 isolated digital inputs, 4 isolated digital outputs for automation purpose

- Pre-calibrated with 0.1micron least count and 0.3micron repeatability. Device can be re-calibrated on-site using aero utility software.

- Powered from universal input SMPS enables the unit to operate from 110VAC to 265VAC 50/60Hz

- Library for .NET available for quick start application software development. Also, explore our PrimeSaverTM software for immediate deployment to multi-gauging systems

- An external converter is required.(Without pneumatic Aero interface).

salient features:

- MS enclosure for light weight and smooth finish. Gives excellent shielding from electro-magnetic noise.

- Non heating and all SMD electronics makes the device durable and noise free.

- Internal double watchdog makes the device always available even in 24x7 operation condition.

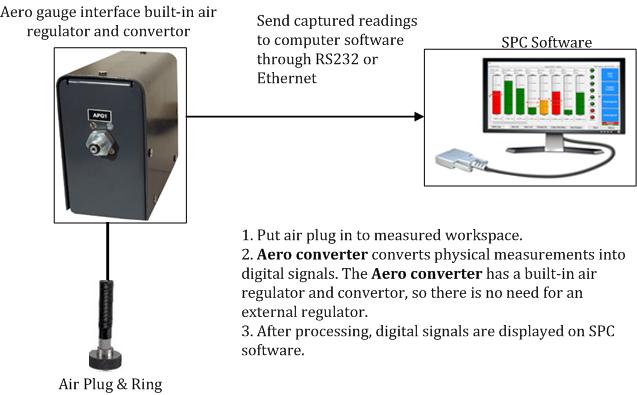

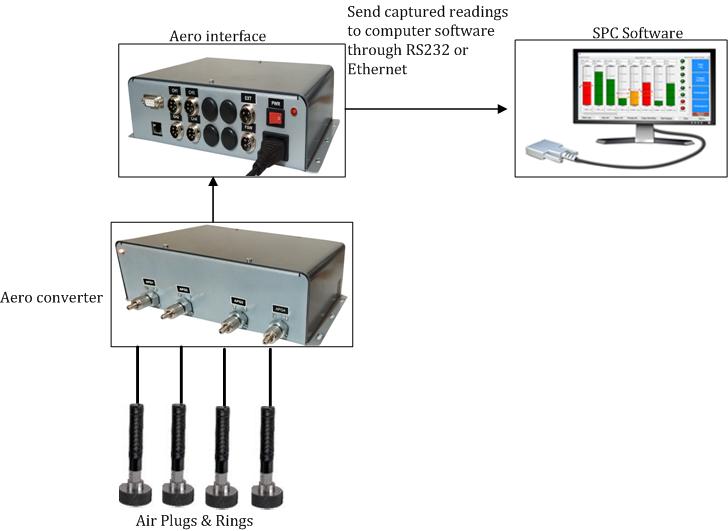

Application diagram

The aero gauge interface is built into the air regulator and converter.

The aero gauge interface requires an external air regulator and converter.

The cascade of multiple interface units.